Top

Search

People also search for:

- Home

- Smart AI Inventory Management: How Leading Brands Use AI to Optimize Inventory

From costly stockouts to excess surplus sitting on shelves, poor inventory decisions are draining revenue faster than many companies realize. That’s why top brands and fast-growing businesses are turning to AI-powered inventory management software for small businesses and enterprises alike to regain control of their supply chains.

Industry trends back this shift. By 2030, nearly 70% of large organizations are expected to rely on AI-based supply chain forecasting to improve demand planning and eliminate manual guesswork. Currently, 89% of retailers are already using or testing AI in their operations.

Predictive analytics and automated reordering can reduce stockouts by up to 35% and cut excess inventory by around 28%. This demonstrates how top brands rely on AI to boost their annual revenue.

This blog will show how leading companies use AI inventory management technologies to reduce costs and avoid stockouts while providing smarter inventory operations, with platforms such as Apidots enabling businesses of all sizes to implement these capabilities more quickly.

Before examining examples, we will look into why AI-driven inventory management has become an important technology changing the way we manage our supply chain.

Historically, companies have utilized traditional methods of managing their inventory using spreadsheets, manual counting and forecasting, and these techniques do not work in today’s complex supply chain environment. AI turns the tide by converting massive data sets—sales history, market conditions, weather patterns, social media sentiment and even local events—into actionable insights.

The use of artificial intelligence and predictive analytics by Nike demonstrates the ability of machine learning to completely change how inventory is managed. Nike has developed a system that utilizes large amounts of data, including historical sales, seasonal patterns, marketing efforts, social media sentiments, and even weather conditions, to accurately predict future demand for its products and adjust inventory levels accordingly. Nike uses computer vision and machine learning as part of its “Nike Fit” program. It uses these technologies to recommend appropriate shoe sizes based on body measurements and shape, thereby decreasing product returns and enhancing inventory management accuracy.

Amazon has a reputation for developing the world’s largest collection of AI-based recommendation systems. The recommendation engine driven by ML is responsible for about 35% of Amazon’s total revenue. The techniques used for making product recommendations provide the basis for inventory management for Amazon; by collecting customer purchases, customer browsing behaviour, and customer location information, Amazon can quickly and efficiently predict product demand and place product locations close to customers in order to reduce the time it takes for a customer to receive their shipment.

Retailers like Target and Zara use AI to avoid overstock and empty shelves. Dynamic pricing and automated replenishment allow them to adjust prices in real time and reorder stock based on competitor activity and demand. Smarter forecasting supported by AI can cut errors by 20–50% and reduce lost sales and stockouts by up to 65%. Smaller retailers are starting with AI-based inventory forecasting or personalized email campaigns.

In restaurants, AI has moved from concept to necessity. The platforms driven by AI leverage historical sales data, climate data, and local events to provide the most accurate forecasts for required quantities of ingredients. Automated ordering using AI takes real-time consumption into account to automate the ordering of ingredients. The use of AI can also identify waste patterns in order to optimize purchasing or portioning amounts. Recipe-based cost management provides advanced alerts to managers of price increases for items on their menus. These capabilities help restaurants reduce food waste, increase labour efficiency, and maintain consistent quality.

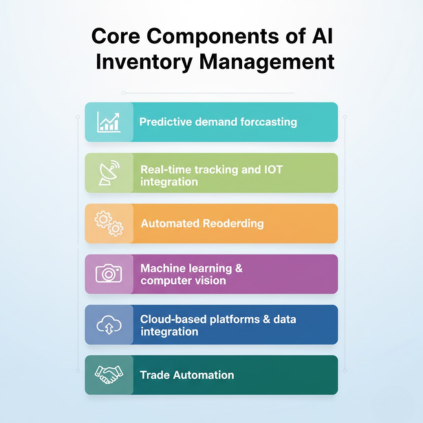

Predictive analytics uses machine-learning models to forecast demand based on dozens (or hundreds) of variables—sales trends, promotions, holidays, weather, social media sentiment, macroeconomic indicators, and competitor actions. By anticipating surges and lulls, businesses can maintain optimal stock and avoid both overstock and stockouts.

For example, sports retailers implementing AI-driven forecasting have reduced stockouts by 35% and excess inventory by 28%. In the supply-chain sector, advanced analytics tools will provide real-time visibility and predictive insights that optimize demand forecasting and inventory management.

The proliferation of specialized sensors, RFID tags, and IoT-enabled devices has enabled the collection of real-time data about the whereabouts and condition of products within a supply chain from a central location through the use of Cloud-based Inventory systems. This substantial amount of actionable data allows companies to track their Pallets, Containers, Delivery Vehicles, and so forth, in addition to monitoring other critical conditions such as Temperature and Humidity.

The resultant visibility has enabled the development of Proactive Decision Systems. Companies now have the ability to reroute shipments when disruptions occur and maintain real-time stock levels across all sales channels.

Automated reordering developed from the application of AI-based reordering on a sale-by-sale basis and the continual analysis of sales and consumption behaviours on a per-product basis. The traditional approach to reordering involves waiting until stock reaches a predetermined threshold. AI systems provide retailers with insight into when demand will be high enough to warrant a reordering and place an order well in advance of, and therefore, when to time an order. Retailers also utilize Dynamic Pricing to adjust prices on a product-by-product basis as demand and the supply chain fluctuate.

Machine-learning models identify patterns in unstructured data—images, video, sensor data—that humans would struggle to analyze. Warehouses collect data like product images, videos from autonomous mobile robots, and diverse SKU formats. Machine learning can spot defects in products or packaging, ensuring customers receive quality goods. Computer vision solutions help customers find the right product size, reducing returns and improving inventory accuracy.

Centralized inventory data on cloud platforms provides access to inventory data and the ability to integrate with ERP, POS and eCommerce systems from any location. Online inventory management systems reduce capital costs, provide updated software and offer superior security and resiliency compared to what most companies could create for themselves.

With online inventory management systems, a company can quickly expand to new warehouses or temporary fulfilment centres, as well as utilize GPS-based tracking of inventory in transit.

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs), which assist with transporting inventory within a warehouse, minimize manual labour and assist in reducing the time required to process an order. Predictive Picking Software utilizing Artificial Intelligence (AI) is used by a company to start the process of fulfilling a customer’s order before the order has been placed.

Warehouse automation merges machine learning, robotics, and analytics; for example, AI directs workers to pick all items needed for the next 24 hours in one trip. In restaurants, voice-enabled stocktakes and AI-driven menu optimization are emerging trends.

AI inventory management is evolving rapidly. Several trends—reflected in rising search interest for phrases like “autonomous supply chain,” “digital twin inventory,” “edge computing in logistics,” “voice-enabled stocktaking,” and “sustainable AI supply chain”—will define the next few years:

Sustainability and Environmental, Social and Governance (ESG) compliance are becoming increasingly important as many companies look to incorporate sustainability into their inventory decisions. Companies will use Artificial Intelligence (AI) to help them reduce their carbon footprints and waste during the inventory decision-making process.

As more companies start to incorporate sustainability into their overall business strategies, we expect to see greater focus on renewable energy and sourcing products in a more responsible manner. Furthermore, there has been a dramatic increase in search traffic for “Green Supply Chain Analytics” and “Carbon Aware Inventory Management.”

The current geopolitical climate is greatly impacting the way that many companies operate and, as a result, we are witnessing a “shift” to move their manufacturing closer to where they sell their products in an effort to mitigate risk and enhance the ability to respond quickly. Using AI will allow brands to better balance both global and local inventory flows.

Apidots offers AI-powered inventory management solutions tailored to retailers, manufacturers and restaurants. Our platform uses predictive analytics to forecast demand and optimize stock levels, integrates real-time tracking via IoT sensors, and automates reordering and dynamic pricing. We also provide cloud-based dashboards that unify inventory, sales and supplier data, giving decision-makers a 360-degree view of operations. Whether you’re a large enterprise or a growing small business, Apidots’ AI inventory management software can help you reduce carrying costs, prevent stockouts and improve profitability.

Contact Apidots today to see how our solutions can transform your inventory operations and give you a competitive edge in the era of AI-powered supply chains.

We leverage AI, cloud, and next-gen technologies strategically.Helping businesses stay competitive in evolving markets.

Consult Technology Experts

Hi! I’m Aminah Rafaqat, a technical writer, content designer, and editor with an academic background in English Language and Literature. Thanks for taking a moment to get to know me. My work focuses on making complex information clear and accessible for B2B audiences. I’ve written extensively across several industries, including AI, SaaS, e-commerce, digital marketing, fintech, and health & fitness , with AI as the area I explore most deeply. With a foundation in linguistic precision and analytical reading, I bring a blend of technical understanding and strong language skills to every project. Over the years, I’ve collaborated with organizations across different regions, including teams here in the UAE, to create documentation that’s structured, accurate, and genuinely useful. I specialize in technical writing, content design, editing, and producing clear communication across digital and print platforms. At the core of my approach is a simple belief: when information is easy to understand, everything else becomes easier.